Many people asked the background process of product design, so I would like to share with you my experiences in both large fortune 500 and small companies. Having designed hundreds of products spanning every industry out there (Aerospace, IoT, Telecom to Audio). The fundamentals end goal of having a quality product designed in a timely manner. The new product design timeline typically spans ~1 year in consumer product to 5 years in aerospace. During the process many trade offs between customers/marketing expectations to what is achievable within the current engineering environment (cost/schedule).

1st step is the Industrial design / concept phase where the marketing department discusses with customers, market trends and internal teams to create a product concept proposal. This proposal should indicate the marketing opportunity, development cost and expected market acceptance/fit including ROI. It is always imperative to follow Steve Jobs' technique of simple, elegant and user friendly.

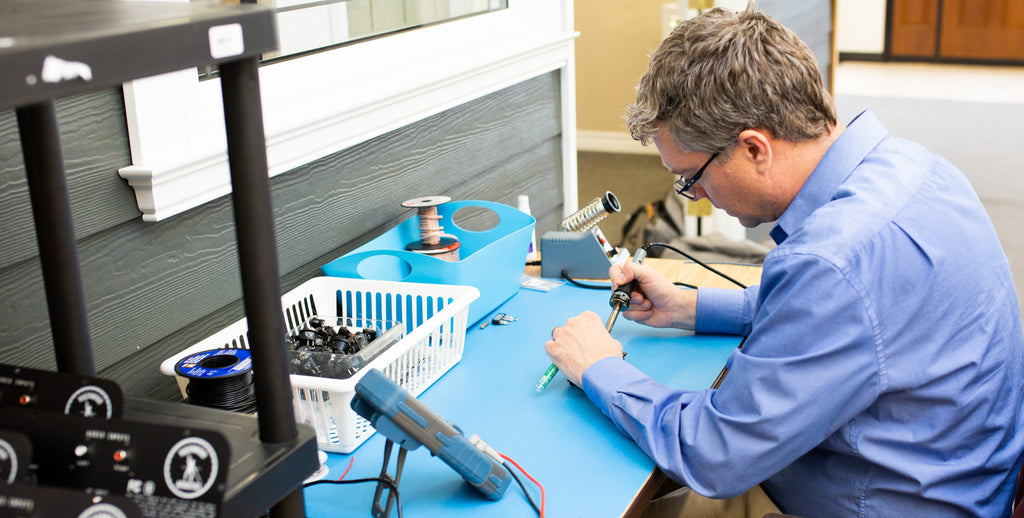

2nd stage is the Preliminary design phase where the mechanical and electrical designers simulate and create the early concept hardware, software and product drawings for the prototype. An early prototype design allows the team to iterate and improve the design and perform early validation testing. The electronics are made using quick turn assembly by hand and mechanical parts are often 3D printed. This is where scott works his magic in the wood shop to handcraft some stellar woodworking cabinets. The primary reason we use only old growth timber is due to its ultra density which is optimal for acoustics.

3rd stage is the Detailed design phase where the prototypes are tested by hardware and further simulations and fine tuning occurs. Often this phase will take months as the design needs to be perfect for future production. It is imperative that the design meets the expected results and things like manufacturability to be completed. Iterations in our anechoic chamber or listening rooms occur often late in the night.

4th stage is Verification and validation phase. The goal is to create the actual 1st design verification sample and do complete full system testing. In acoustics you verify the amplifier, acoustic response and long term reliability/endurance. All production tooling and processes are verified. If the device is a powered one you will have various industry standard testing to complete such as FCC or CSA/UL/CE.

5th stage is the most satisfying/nervous state of a product designer. New Product Introduction is the start of the first formal production run. Typically you keep this production run 30 to 100 units to ensure proper quality control mechanisms are in place and complete audits are completed. Continuous improvement in production systems are instituted to ensure 100% quality and efficiency.

Obviously, most of these stages have many sub tasks but overall this is the reason why product design development can be costly and take a lot of hard work. Teamwork between all disciplines and reviews are critical at each stage of the design.

Next time you pick up a product stop and think about how much engineering design and marketing to create a product. Oftentimes we forget and take the simplest of things for granted such as a simple click of buying a product of the internet. As a product designer, there is no greater joy than having people enjoy your products so ensure you leave reviews and comments to help validate their hard work.

In our company, Riverwood Acoustics, we have taken an additional step of locally sourcing manufacturing subcontracts. Everything from our woodworking cabinet making, metal work to our packaging is completed within an 100km radius of our company. This is imperative for us to utilize local companies to improve our economies, enhance quality feedback and build relationships with our communities.

Keep signed up to our email list for future blog posts. If anyone wants to learn more about the process please don't hesitate to reach out or comment below.