The Building Process

It started over a century ago when the logs were floated down the Ottawa River during the 1800s great timber drive. Many of these logs sunk to the bottom during the journey and lay at perfect preserved for over a century.

Our eco-divers retrieve this historic timber for multi stage processing (cutting and kiln drying). The result is a premium grade A1 ultra dense birch wood ready for our sculpting into our cabinet.

This one of a kind Riverwood has is handcrafted utilizing the latest CNC tools available for precise cutting and ensuring perfection.

Each cabinet is set clamped overnight in our custom vice network to ensure perfect sealed enclosure and strength.

Sanding, sanding and more sanding before going into the no dust painting facility. Our walnut finish gets a triple finish of custom varnish and lacour coating.

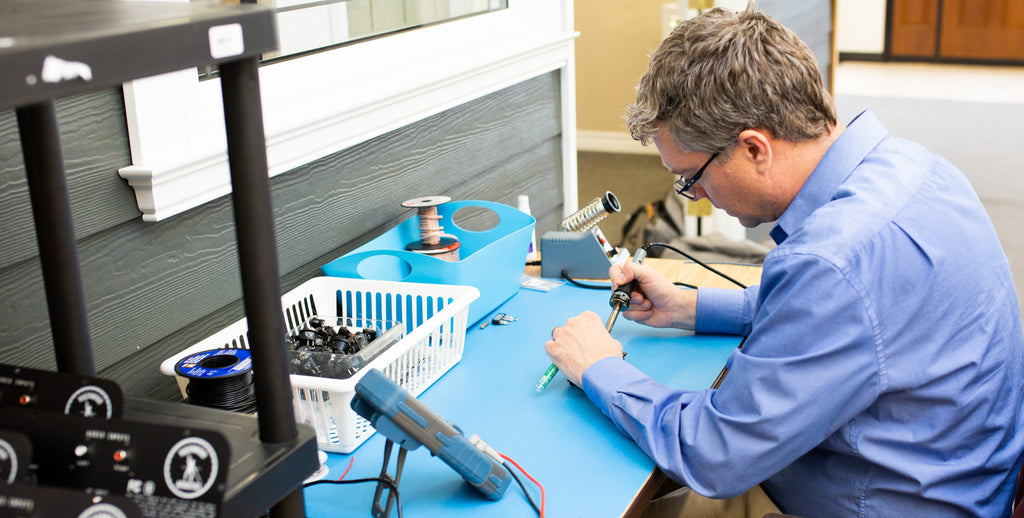

Hand soldering using Silver blend for the electronics amplifier and speaker termination is completed in our Renfrew production facility.

Final assembly and testing occurs before transitioning to quality control for final verification before packaging/shipping to you for your enjoyment.

We hope you enjoyed the process and if you have any questions please don't hesitate to ask. Welcome to the Riverwood family.