You wouldn’t know it but some of the wood used in our Hudson speakers is over 300 years old! The story of how they got there begins with the start of the logging trade in the Ottawa river.

In the beginning of the 19th century, Great Britain, at the time affected by the wars ravaging Europe, was unable to have access to their normal supply in the Baltic, feeling the effects of Napoleon’s blockade. This forced them to lean heavily on Canada to supply them with the vast amount of timber needed for their Navy. This demand helped grow the surrounding region and spur development along the river. Turning the Ottawa river was a major trade artery in which timber flowed from the wilds of Canada to foreign markets.

Philemon Wright is credited for bringing the first raft of timber down the river from the Ottawa Basin to Quebec around 1806. They christened the raft “Colombo,” with the journey taking them around three months to complete due to the raft repeatedly breaking and navigating the rapids in certain sections of the river. The rafts themselves were made from the lumber itself, most of it squared timber, They cut the logs into squares, lashed them together into a larger structure and constructed huts on top for the workers to live in while they made the journey to Quebec,where the lumber was dried and shipped out. Every spring saw such rafts dotting the many tributaries of the Ottawa river as lumberjacks made their way down to cash in on their product. People called them “stick-men” due to the fact that when the rafts became stuck they would spring up, longs sticks in their hand, and try to push the raft away from whatever was stopping the raft.

The entire process from start to finish was painstaking and arduous. The lumberjacks spent most of their time in isolated camps far from civilization.

From cutting down the trees in Canada's hinterlands, to sawing them down, making the lumber into rafts and then making the treacherous journey through rapids and waterfalls to Quebec. The journey wasn’t a pleasant cruise, with rapids and waterfalls along the way. Sometimes they even had to disassemble the raft to get around such obstacles, then reassemble them on the other side. Often the rafts would break apart, claiming the lives of the men piloting it. The profits these men were chasing where substantial, around 1850 a single raft would be approximately $12,000. At the end of the century, as timber supplies diminished the prices rose to around $100,000 or a single raft. Adjusted for Inflation $12,000 in 1860 would be around $346.998, and in 1890 $100,000 would be around $2,637,439. Certainly the payout awaiting the men at the end of their journey seemed worth the peril.

Not all of the logs made it to their destination. Some fell to the bottom of the river due to the rafts breaking apart or the wood they were transporting became heavy with water and sank. There at the bottom of the riverbed they became covered in sediment, with the pressure helping to preserve them. It’s these logs that Riverwood uses for their speakers, but first they have to be recovered from the river.

Have you ever heard of a logging company that doesn’t cut down trees? Well now you have:founded in 1997, Logsend specializes in retrieving those lost bits of Canadian history. They’re the number one exporter of old-growth timber of Canada and do so in a completely sustainable fashion. Dredging up wood from the bottom of a river that at some parts is 402 feet deep is no simple task. First, trained scuba divers plunge into the icy waters in order to find and mark the logs. Each log has floatation devices tied it, and is lifted out the riverbed to avoid disrupting the surrounding environment. A tug boat then comes, hooks the logs, lifts them up enough so they’re not dragging along the riverbed and brings them to shore. Then they’re picked out of the water and sent to be processed. The logs are then sawn and place them to air-dry, which can take anywhere from 3 months to year. The air-dried logs are then sent to a dry-kiln and fashioned into a wide array of products, such as custom hardwood flooring, moulding, and the paneling that you see on Riverwood’s own speakers.

The recovered logs are considered Old-Growth, meaning they had the opportunity to grow uninterrupted for hundreds of years. The annular rings of Old-Growth wood is tighter, results in an ultra dense wood cabinet produce an unparalleled tone.Here at Riverwood Acoustics, we’re proud to partner with a company dedicated to helping the environment through sustainable manufacturing methods. Our priorities when designing the Hudson was to make utilize local manufacturing to ensure quality, local jobs and minimize carbon footprint. By working with Logsend, we’ve taken one step closer to achieving that goal.

If you’re looking to own a piece of history, take a look at our Hudson speakers. Available in either a natural or walnut finish, the Hudson produces an unrivaled, crisp sound. Countless hours went into perfecting the design, style and acoustics so that you will enjoy for a lifetime.

Riverwood Acoustics has committed to providing sound for the Arnprior museum exhibit that will be showcasing some treasures from the historic logging drive. The new exhibit is going to be ready in the early summer and should be on everyone must do list.

Historic, Artful, Unrivaled.

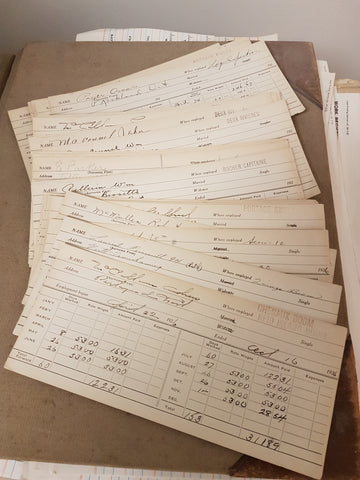

Photo credit: Arnprior/McNab archeives

Article by: Johnathan Larkey

LogsEnd. Ottawa based flooring company specializing in premium reclaimed old growth timber. Must check out their new showroom on Iber Rd, Ottawa, ON